Introduction

Understanding Seal End Auto Bottom Boxes

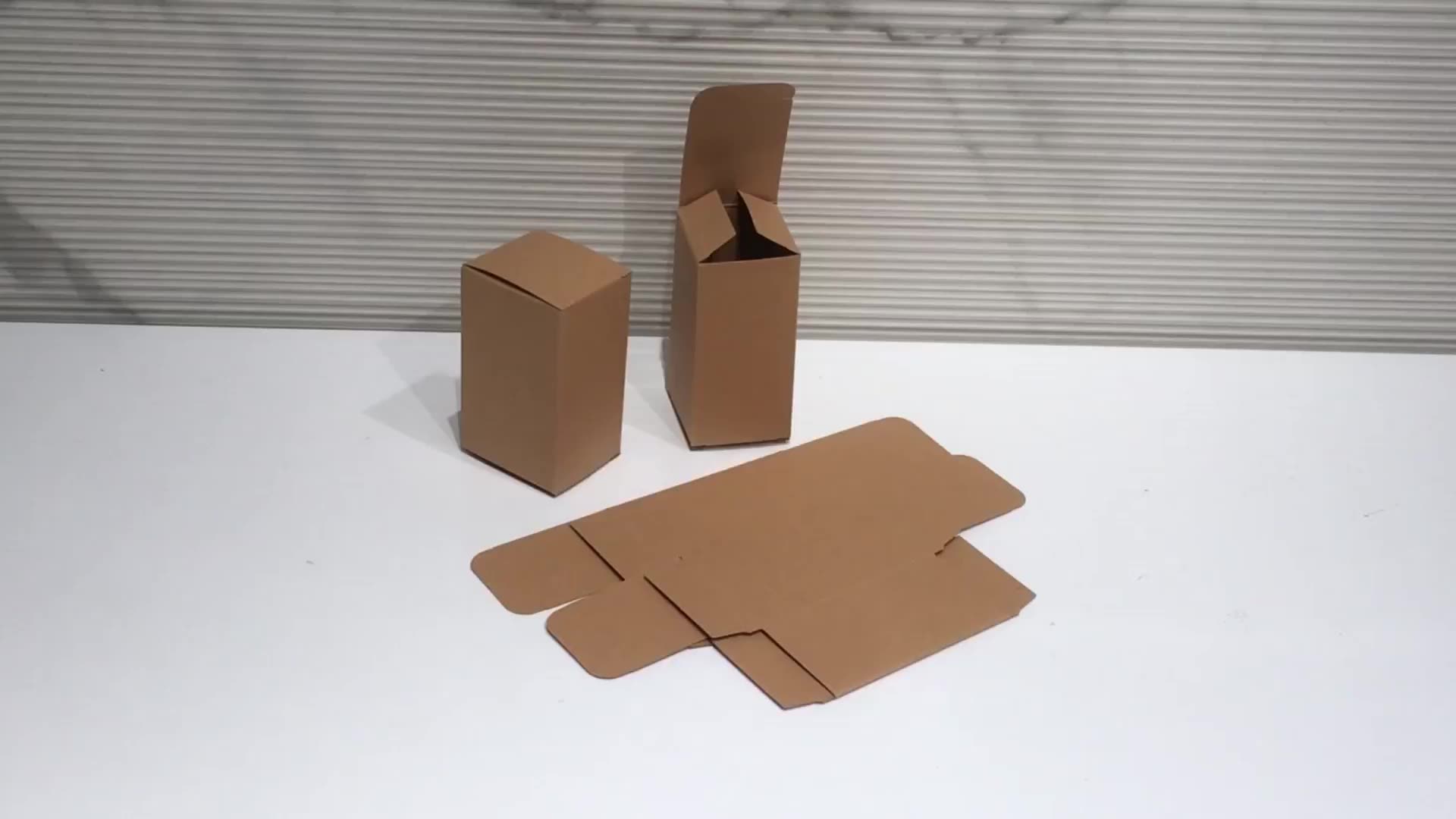

Seal End Auto Bottom boxes, also known as crash-lock bottom boxes, are a type of folding carton characterized by their unique bottom closure mechanism. Unlike traditional packaging boxes that require manual assembly and sealing, SEAB boxes feature an automatic bottom design that locks into place when the box is assembled. Additionally, the seal end closure at the top provides added security and protection for the packaged contents.

Design and Construction

Seal boxes are typically constructed from durable paperboard or corrugated cardboard, offering strength and rigidity to protect the enclosed products. The automatic bottom closure mechanism eliminates the need for adhesive or tape, simplifying the assembly process and ensuring a secure seal. The seal end closure at the top provides additional tamper-evident features, enhancing product security during transit and storage.

Applications Across Industries: Seal End Auto Bottom boxes find versatile applications across various industries:

- Food and Beverage: SEAB boxes are commonly used for packaging snacks, confectionery, baked goods, and other food items, providing a hygienic and secure packaging solution.

- Retail: In the retail sector, SEAB boxes are ideal for packaging cosmetics, pharmaceuticals, electronics, and other consumer goods, offering both functionality and branding opportunities.

- E-commerce: With the rise of e-commerce, SEAB boxes are widely used for shipping and packaging products sold online, ensuring safe and efficient transit from warehouse to customer.

- Promotional and Marketing: SEAB boxes can be customized with branding, logos, and promotional messages, making them a popular choice for product launches, marketing campaigns, and corporate gifts.

Custom boxes offer a versatile and customizable packaging solution that allows businesses to showcase their brand identity while providing protection and functionality for their products.

Benefits of Seal End Auto Boxes

- Efficiency: The automatic bottom closure mechanism streamlines the packaging process, saving time and labor costs associated with manual assembly and sealing.

- Security: The seal end auto bottom boxes at the top provides added security and tamper-evident features, safeguarding the packaged contents during transit and handling.

- Strength and Durability: Seal boxes are constructed from sturdy materials, offering protection against damage, crushing, and moisture, ensuring the integrity of the packaged products.

- Customization: Seal boxes can be customized in terms of size, shape, design, and printing, allowing businesses to create unique packaging solutions that reflect their brand identity and messaging.

- Cost-Effectiveness: The efficient design and automated assembly of SEAB boxes result in cost savings in terms of material usage, labor, and shipping expenses.

Conclusion

Seal End Auto Bottom boxes represent a versatile and efficient packaging solution for a wide range of products across industries. Their automatic bottom closure mechanism, combined with the seal end feature, offers convenience, security, and branding opportunities. As businesses continue to prioritize efficiency, security, and cost-effectiveness in their packaging strategies, SEAB boxes are poised to remain a preferred choice for streamlined packaging solutions in the ever-evolving marketplace.